What Equipment & Supplies Are Required for Powder Coating?

Powder coating is an electrostatic process used to strengthen materials and surfaces in many industries, including automotive and industrial. But if you’ve never done this process and don’t know where to start, or you’ve tried it in the past and didn’t get the results you were hoping for, we’re here to help. First things first, you’ll need to be equipped with all the right equipment and supplies, so that’s exactly where we’re starting.

The powder coating process can be quite complex, and there are a few things you’ll need to have to hand to ensure that the coating is applied properly. Below, we’ve broken down the required equipment and supplies into simple lists so you can make sure nothing is forgotten.

What supplies are required for powder coating?

Let’s start with the supplies you’ll need before you can get started with powder coating, including primer and masking products.

Primer

As with most coating applications, you’ll need a primer to help it stick to the material properly.

For powder coating, you’ll usually need a corrosion-resistant primer since this will prevent rusting and corrosion under the powder coating. This is the best way to ensure the coating can do its job and last longer. Typically, an epoxy primer should be used for this, so make sure you have this to hand.

Masking products

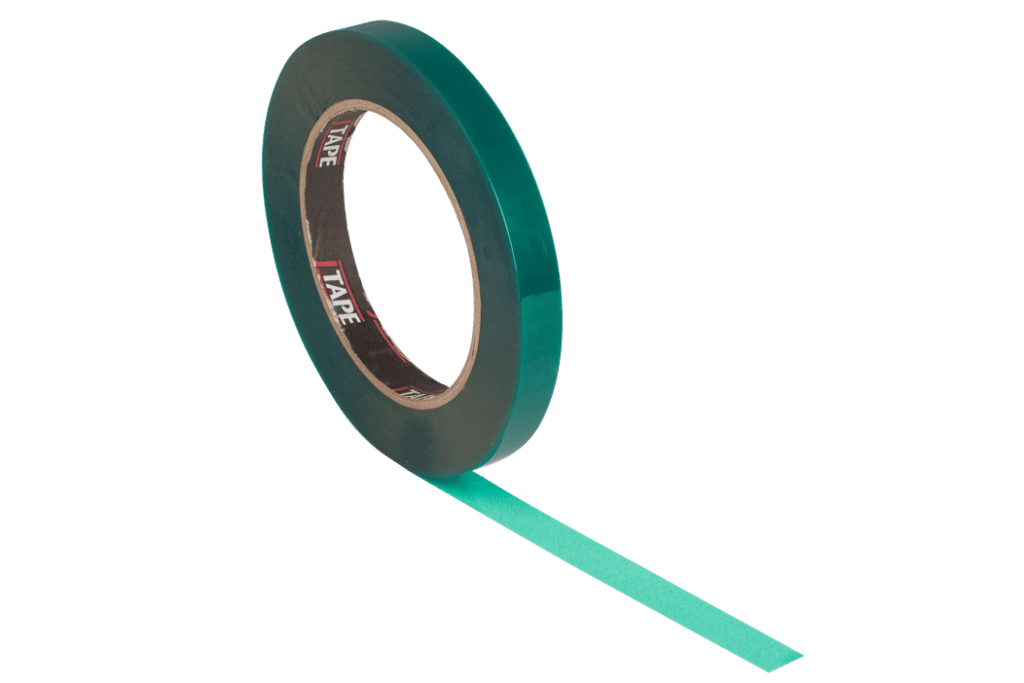

The masking supplies you use for powder coating must be durable and capable of withstanding the high temperatures they’re exposed to during the process. We recommend using our Green High Temperature Polyester Film Tape and Blue High Temperature Polyester Film Tape since these both offer excellent temperature resistance of up to 220°C/428°F for up to 30 minutes. Working on a curved surface? You can easily mask it off with the thinner and more flexible blue variation of our tape. Powder coating a flat surface? Go with our green variation with its increased thickness and durability.

During alloy wheel powder coating specifically, you might also need to protect the rear hub. Our Green High Temperature Polyester Film Discs are the ideal solution and something we would recommend using when powder coating this surface. The polyester film discs are temperature-resistant up to 220°C/428°F for up to 30 minutes, and like the tapes they were modelled on, they provide a perfect finish each time.

Powder coating materials

Finally, for the supplies, you’ll need to have the powder coating materials. This includes the polymer resin coating and the curatives, pigments, levelling agents, flow modifiers, and other additives that will be mixed with it.

What equipment is required for powder coating?

Moving on to the kinds of equipment you’ll need, below you’ll find a basic list of what should be used to carry out the powder coating process on materials and surfaces.

Tools for disassembly

Depending on the material you’re working on, you might need to disassemble some of the parts to ensure your coating is evenly and properly applied. This might require a wrench, screwdriver or pliers, so check the material to make sure you have the necessary tools before you go ahead with the rest of your powder coating preparation [Link to blog when live].

Sandblasting equipment

Part of the preparation will require you to sandblast the material or surface. This will give it the texture needed to help the coating stick and settle into the material, giving it the durability you’re seeking. For this step, you’ll need a sandblasting machine, abrasives and dust collectors.

Powder coating gun

A powder coating gun is needed for applying the powder coating mixture. These guns can be manual or automatic and provide the control necessary to achieve for the desired finish. A powder coating gun will push the powder through with compressed air, and then the electrostatically charged coating can spread across the surface.

Spray booth / extraction unit

The powder coating should be applied in a spray booth that’s large enough for the surface. This should be properly ventilated to ensure the coating is filtered out and doesn’t linger in the air. The temperature should also be controlled to ensure the coating doesn’t melt as it’s being applied.

Curing oven / plant

There are a few different types of self-contained curing plants and ovens, and the type you have will likely depend on the industry you’re in and the size of your establishment. From compact curing ovens to industrial ones, just make sure that yours is fit for purpose and is the most cost-effective option for you. The main thing to remember is that the powder coating must be cured at high temperatures to melt it into the surface, so check that your curing oven or plant can achieve these levels.

PPE

Protecting yourself during this process is crucial since you’re dealing with high temperatures and chemicals. Because of the dust that’s produced during powder coat preparation and the powder coating process itself, it’s recommended to wear a respirator that filters this out. Temperature-resistant gloves and clothing should also be worn to protect you from burning yourself during any part of the process. Additionally, hard-toed boots are recommended when working with heavy materials, which is likely in the industries this coating is normally used within.

Powder coating can involve a variety of different equipment types depending on the application, but we’ve covered the basics to help you get started. Before you begin this process, you should make sure you’re properly prepared and understand exactly what you’re doing. For more insights and advice on automotive painting applications and techniques, check out our JTAPE blog.